Infrastructures

Resources

.

| Total Area | 35200 SQ MTR |

| Office Area | 250 SQ MTR |

| Shed Area (Area under Crane) | 12500 SQ MTR |

| Power Source | 33 KVA High Tension (From CSPDCL) |

| Substitute Power Source | 63 KVA Generator (KIRLOSKAR) |

Manufacturing Facilites

.

| Description | Range / Make |

| Beam / Column fabrication and welding equipments fully automatic beam welding system for star, plus, i & h beam fabrication + welding & straightening – 2000 tonnes per month | |

| Material Processing and Forming Equipments | |

| Plate Bending Machine |

|

| Plate Bending Machine | 30 mm THK X 2.5 Mtr Wide |

| Plate Bending Machine | 16 mm THK X 1.8 Mtr Wide |

| Hand Press Machine | Screw Driven |

| Hydraulic Press | 2000 Ton Capacity |

| Hydraulic Flange straightening / Beam Forming Machine | 800 Ton Capacity |

| Column Drilling Machine (Horizontal Boring Machine) | Dia 60 mm Capacity |

| Hand Drilling Machine | Dia 25 mm Capacity |

| Magnet Base Drilling Machine | Dia 25 mm Capacity |

| Lathe Machine | 6ft Long Bed |

| Radial Drilling Machine Batliboi Make | Dia 75 mm Capacity |

Welding Equipments

.

| CNC Cutting Machine – With Four Stations | 200 mm THK Kirloskar & Flame Tech Cutting Systems |

| Plasma Arc Cutting Machine (for ALLOY / SPECIAL GRADE STEEL) | 125mm THK / ADVANI Make |

| Hand Gas Cutting Set | 125 mm THK / ESAB Make |

| Portable Auto. Pug – Cutting Machine | 125 mm THK / ESAB Make |

Quality System & Welding System

.

Welding and Welding Process Control

- Welding Equipment: – Calibrated

- Electrode Storage: – As Specified

- Weld Procedure Specifications (WPS) and Procedure Qualification Record (PQR)

- Welder Performance Qualification (WPQ)

- Redrying of Electrodes

- Controlling the Welding Quality

Stages of Welding :- As Specified

- Pre Welding

- During Welding

- Post-Welding

- Rectification of Welds

- Final Inspection

Final Welding Inspection (Visual)

- Type of defects / flaws

- Parent metal damage

- Cleaning of weld

- Surface crack

- Surface Flaws

Repair Procedure of Weld Defects: -

.

As Required

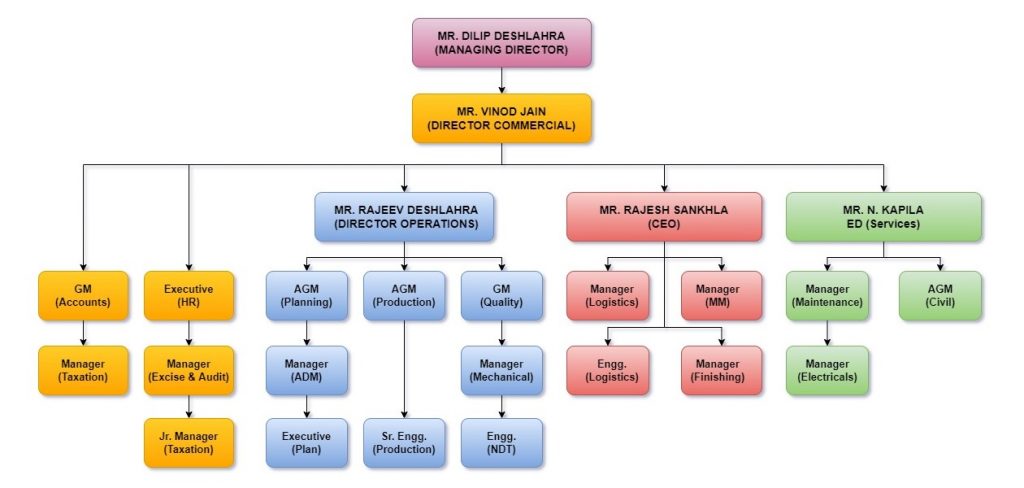

Organization Hierarchy

.